.jpg)

.jpg)

(5).jpg)

Tungsten is a refractory metal with the highest melting point. Generally higher than the melting point 1650 ℃ and a storage amount of metal zirconium and melting point higher than the melting point (1852 ℃) of metal is called refractory metal. As a kind of refractory metal, tungsten is the most important advantage is good high temperature strength, good corrosion resistant to molten alkali metals and steam performance.

Custom made Tungsten and tungsten alloy plates/sheets

Grade :W1,W2

Standard:ASTMB760

Application: used in electron, electric light source, electric vacuum and other industries, supply tungsten electronic plate, tungsten boat, tungsten insulation screen, tungsten heating and other products.

Parameter:

|

Grade |

W1,W2,WLA20 |

|

Condition |

Hard (Y)

Vacuum annealing (M |

|

Condition |

Hot rolled (R)

Vacuum annealing (M) |

|

Process |

Powder metallurgy |

|

CNC Turning Machining Range |

Thickness1mm ~ 50mm x 500mmx 1200mm |

|

CNC Milling Machining Range |

850mmx 1600mm x 900mm |

|

CNC Stamping Machining Range |

1.1m x 0.62m (maximum weight: 320T) |

|

Water Jet/Laser Cutting Machining Range |

900mm x 800mm (Tolerance: ≤±0.01) |

|

Certificate |

EN10204.3.1+EN10204 3.2 (BV/SGS/TUV) |

|

Application |

Power plant/Electrode/Chemical |

|

Thickness

|

Tolerance |

Width |

Tolerance |

Length |

Tolerance |

|

|

ⅠGrade |

ⅡGrade |

|||||

|

0.10~0.20 |

±0.02 |

±0.03 |

30~150 |

±3 |

50~400 |

±3 |

|

>0.2~0.30 |

±0.03 |

±0.04 |

50~300 |

±3 |

50~400 |

±3 |

|

>0.30~0.40 |

±0.04 |

±0.05 |

50~300 |

±3 |

50~400 |

±3 |

|

>0.40~0.60 |

±0.05 |

±0.06 |

50~300 |

±4 |

50~400 |

±4 |

|

>0.60~0.80 |

±0.07 |

±0.08 |

50~300 |

±4 |

50~400 |

±4 |

|

>0.8~1.0 |

±0.08 |

±0.10 |

50~300 |

±4 |

50~400 |

±4 |

|

>1.0~2.0 |

±0.12 |

±0.20 |

50~300 |

±5 |

50~400 |

±5 |

|

>2.0~3.0 |

±0.20 |

±0.30 |

50~300 |

±5 |

50~400 |

±5 |

|

>3.0~4.0 |

±0.30 |

±0.40 |

50~300 |

±5 |

50~400 |

±5 |

|

>4.0~6.0 |

±0.40 |

±0.50 |

50~300 |

±5 |

50~400 |

±5 |

|

>6.0~30.0 |

±0.20 |

±0.50 |

50~300 |

±5 |

50~1200 |

±5 |

Tungsten and tungsten alloy bars/rods

Grade:W1,W2

Standard:GB4187-84 / ASTMF288-`1996

Application: electron, electric light source, electric vacuum, tungsten heating etc.

Grade:W1,W2,WAL1,WAL2

Standard:GB4181-84

Application: electric light source and electronic devices.

Parameter:

|

Grade |

Diameter d(mm) |

200mm wire weight (mg) |

200mmwire diameter tolerance(%) |

|

|

Ⅰgrade |

Ⅱ Grade |

|||

|

W1

W2

WAL1

WAL2

|

0.005≤d≤0.01 |

0.65~1.47 |

±2.5 |

±3 |

|

0.01<d≤0.06 |

>1.47~2.61 |

±2.0 |

±3 |

|

|

0.06<d≤0.1 |

>2.61~16.33 |

±1.5 |

±3 |

|

|

0.1<d≤0.15 |

>16.33~256.2 |

±1.5 |

±3 |

|

|

0.15<d≤0.2 |

— |

±1.5 |

±2.5 |

|

|

0.2<d≤0.35 |

— |

±1.0 |

±2.0 |

|

Tungsten CNC Machined Part

Material: Tungstenand Tungsten Alloys

Material characteristics: great high temperature strength, special corrosion resistant to molten alkali metals and steam performance

Melting point: 1852°C

Density : 19.35 g/cm3

Surface: Polished

Drawing: 3D/ CAD

Size & Shape: Custom made

Raw material: Top quality Tantalum rods, Sheets and Tubes

MOQ: 5 pcs

Surface: Polished surface

Roughness: Max 1.6um

Application

Assembly of high temperature equipment

Other equipment and industries that require super corrosion resistance

Tungsten Bolts & Screws

Metric Tungsten Bolts Standard: DIN, JIS, ISO, BS

Inch Tungsten Bolts Standard: ANSI/ASME B18.2.1

Material: Tungstenand Tungsten Alloys

The Most commonly Specification and size used

|

Standard Item |

Size in Bulk Stock |

|

DIN 933 |

M8; M10; M12; M16 |

|

DIN 931 |

M8; M10; M12; M16 |

|

ANSI/ASME B18.2.1 |

1/4” ,3/8”, 7/6” 3/4” 7/8” 5/8” |

|

DIN 912 |

M8; M10; M12; M16 |

Application

Assembly of high temperature equipment

Internal fastening for Power plant equipment

Other equipment and industries that require super corrosion resistance

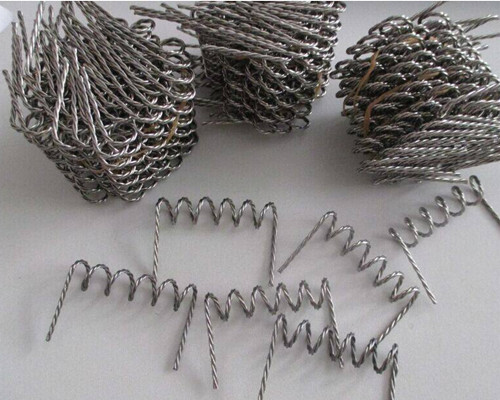

Tungsten Crucible/Boats

Grade : W1 ,W2 ,WAL1,WLA20

Purity:≥99.95%

Tungsten b nuts as DIN/ISO ,M3-M36 MNQ:100pcs

Tungsten crucible/boats :CUTOM made MNQ:5pcs

Application

Assembly of high temperature equipment

High temperature and normal pressure chemical reaction generator for precious metals

If you have any suggestions or opinions about our products,please leave a message,and we will immediately answer your questions. Thanks for your support.